Frame

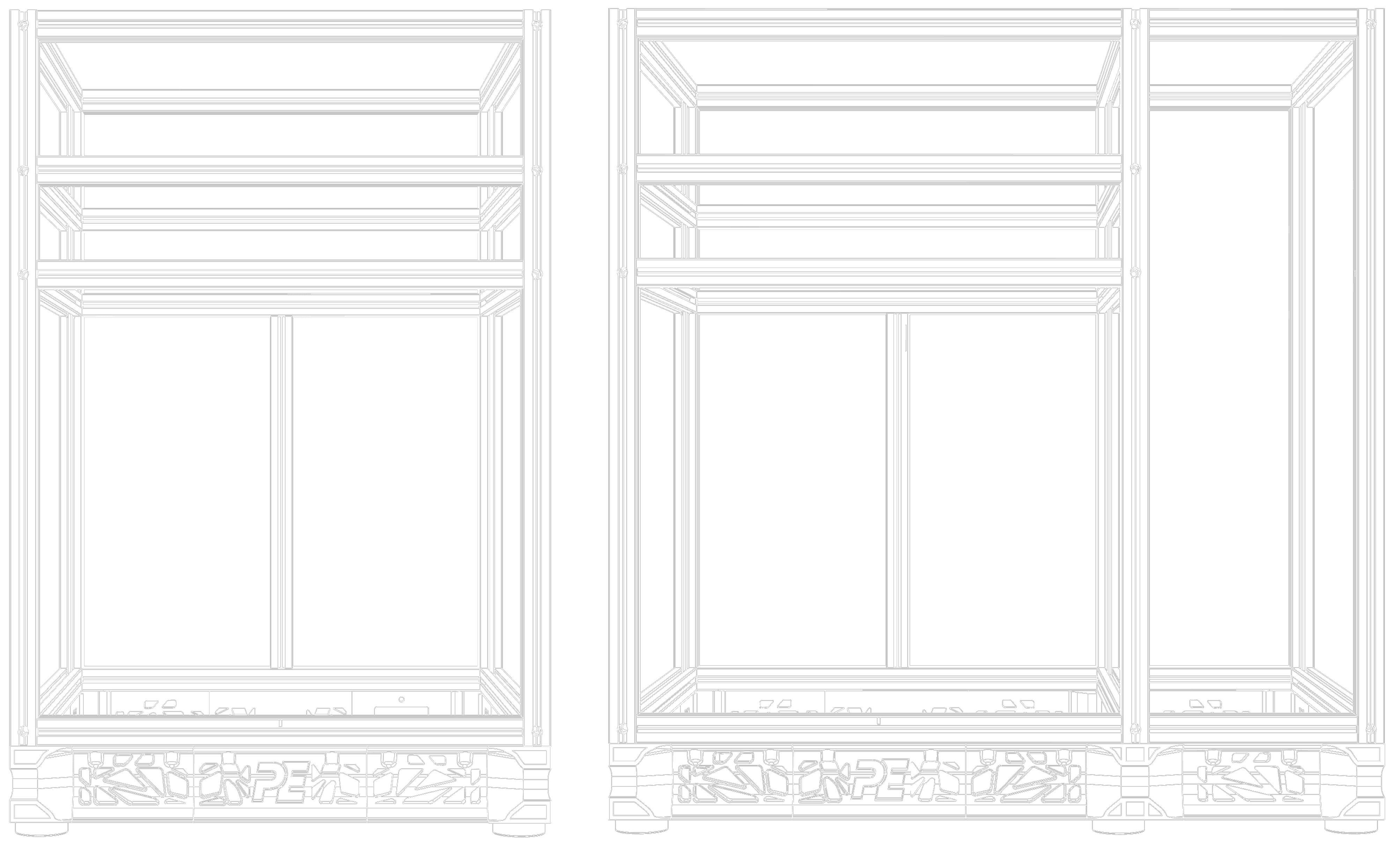

The frames must be assembled perfectly parallel to each other, as this plays a crucial role in the performance of the printer. On this page, we will discuss the two different frame options supported by the Crossant, the assembly methods (blind joint, corner bracket), and the tools you will need.

Frame Selection

Crossant offers two different frame options: Sidepack and Default. You can click here to see the advantages and disadvantages of each frame compared to the other.

Fixing Methods

There are two options for assembling the frame: Blind joints and corner brackets.

tipWhen assembling the frame, do it on a flat surface like marble or glass to ensure accuracy, and definitely use an angle smith.

Blind Joints

For assembling the frame, we use the blind joint method for nearly 95% of the connections. For blind joints, you need to drill access holes on the extrusions and tap the ends of the extrusions. Click here for more detailed instructions.

Since the extrusions are made of aluminum, overtightening the bolts can damage the threads.

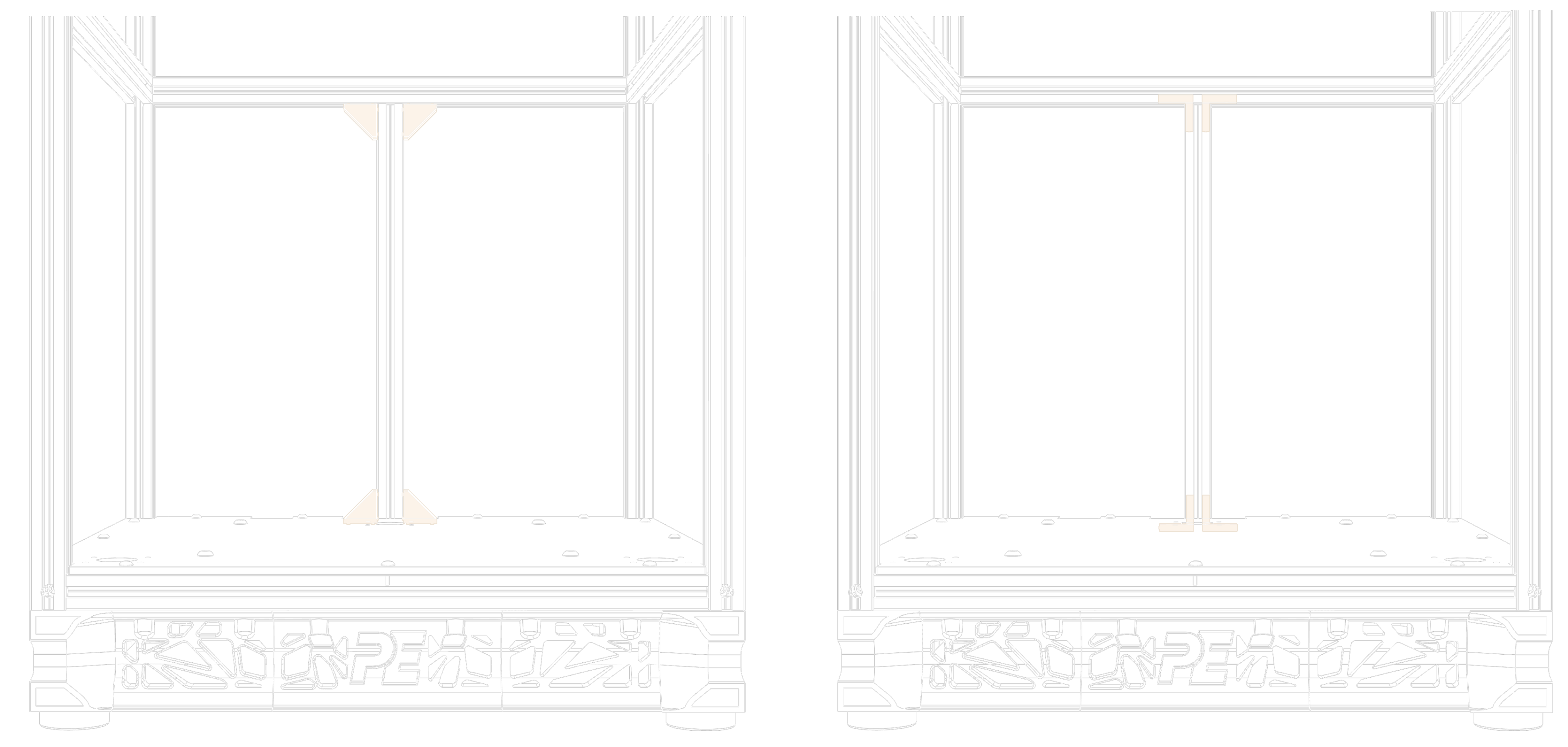

Corner Brackets

There are only a few places where we use corner brackets in the Crossant. If you are using the Sidepack frame, they are used for the Sidepack assembly. If you are using the rigid Z-axis, they are used to secure the extrusions under the bed together. In both frames, we use corner brackets to secure the extrusion that holds the rear Z rail

You can use two different types of corner brackets. One is a slot-in corner bracket (on the right), and the other is a regular corner bracket (on the left). While the slot-in type may look more aesthetically pleasing, we recommend the regular one.

T-Nuts

In the assembly of the printer, T-nuts are used in many places and in large quantities. You have three options for T-nuts: hammerhead (on the left), in-slot T-nut (on the middle), and roll-in T-nut (on the right).

Hammerhead T-Nuts

The hammerhead T-nut is the most cost-effective option among the three and, in terms of assembly, is more advantageous than the in-slot T-nut but more challenging than the roll-in T-nut. You can use this T-nut for almost every part of the printer.

Insert T-Nuts

Insert T-nuts are the type that provides the strongest connection among the options. Due to their shape, they slide into the extrusions, making post-assembly adjustments impossible, which complicates their installation. They are a good option for securing rails.

Roll-in T-Nuts

Roll-in T-nuts remain fixed in place within the channel due to the preload on them, which makes them advantageous in terms of ease of assembly. However, they are the most expensive option among the types.